About Yaoshengda

Specializing in the production of various materials rivet nuts, bolts, shaped parts, carbide molds, diamond wire drawing dies

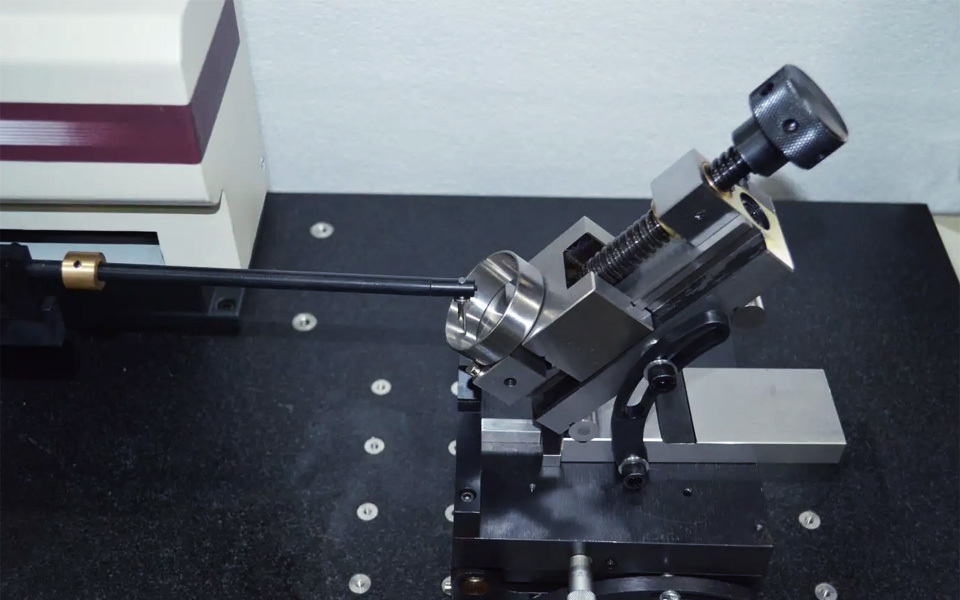

We purchase some new high-end equipment, new mold making technologies and devices, and import multi-station cold headers, relying on which as well as nearly 20 years of experience in mold making, we provide our clients with more professional services and technical exchanges, improve the service life of the mold by three to five times and help clients to reduce much more production costs, achieve more stable product quality and lower management costs at the same time.

Company established in 2017

More than 300 kinds of product series

More than 30 professional production equipment

80% automated

Our Products

Specializing in manufacturing all kinds of sleeve molds, nut molds, special molds, fastener molds and tungsten carbide molds. Special steel is imported from Taiwan and most of the materials are tungsten carbide steel.

News & Information

In order to serve customers, the company has non-standard design team, equipment debugging, technical exchanges, mold research and development, etc.

Sep 15,2023

Anti loosening nut is an important device to ensure reliable connection

Firstly, the anti loosening nut adopts a special structure and working principle, which can provide additional locking force to prevent the nut from loosening. It usually has a washer or spring structure, which can generate additional pressure under force and vibration to fix the nut in the threaded hole, effectively preventing loosening and detachment. Anti loosening nuts can be selected according to different needs, such as spring washers, lock nuts, etc. Secondly, the installation and use of anti loosening nuts are relatively convenient. During the installation process, lock nuts are usually similar to regular nuts, using the same installation tools and steps to ensure stable installation. When using anti loosening nuts, no additional tools or operations are required, just tighten according to the correct torque requirements. Thirdly, anti loosening nuts are widely used in various fields. Whether in the fields of mechanical equipment, automotive manufacturing, construction engineering, or aerospace, lock nuts play an important role. It is commonly used for connections that require resistance to vibration and looseness, such as wheel nuts, engine components, aviation equipment, etc. By using anti loosening nuts, the connection can be maintained firmly and stably, improving the efficiency and safety of equipment and structures. Then, in terms of maintenance, the lock nut is relatively simple. Regularly check the tightening status of the lock nut to ensure the stability and safety of the connection. If loose or deformed nuts are found, measures should be taken in a timely manner for inspection and adjustment to maintain the reliability of the connection.

Sep 15,2023

The principle and advantages and disadvantages of anti loosening nuts

Anti loosening nuts are made of special engineering plastics attached to the threads of the nuts. When used with bolts, these nuts cause the internal and external threads to be compressed by the engineering plastics during the tightening process, resulting in a strong reaction force, greatly increasing the friction between the internal and external threads and providing resistance to vibration. This resistance is completely distributed throughout the entire meshing section of the internal and external threads, and this friction force is independent of the tightening pressure between the internal and external threads. Unlike previous stopping methods, it relies on the friction force generated by the pressure after the screw is tightened to play a stopping role. Once the screw is slightly loosened, the pressure decreases, and the friction force quickly disappears and loses the stopping effect, causing the screw to loosen. Advantages of locking nuts: Superior seismic performance: The normal force generated by tightening the anti loosening nut is much greater than that of ordinary standard nuts, which has a greater anti loosening and anti vibration ability. Strong wear resistance and shear resistance: The 30 ° inclined surface of the nut thread base can evenly distribute the locking force of the nut on all the threads of each tooth. Due to the uniform distribution of compression force on the thread surface of each tooth, the nut can effectively solve the problems of thread wear and shear deformation. Long service life: The rubber ring of the anti loosening nut has good flexibility, weather resistance, and is not easy to loosen. The locking performance still maintains its original effect after repeated disassembly. Disadvantages of locking nuts: Unable to adapt to harsh environments. The temperature is too high or too low, which has a significant impact on the locking effect of the anti loosening nut, and the locking effect of the nut is greatly reduced. The quality decreases after electroplating heat treatment. During heat treatment, it is easy to cause residual foreign objects on the nylon surface and damage the threads. Anti loosening nuts are widely used in agricultural machinery, public facilities, and other fields due to their integrated nature, convenient installation, reusability, and no need for washers.

Add WeChat Learn more

Wujin Luoyang Yaoshengda Hardware Factory

Branch Address 1: Gaozhao Industrial Zone, Jiaxing City, Zhejiang Province, China

Branch Address 2: Mozi Kichuang Park, Tengzhou City, Shandong Province, China

Headquarters Operation Center: Wanda Center, Wujin District, Changzhou City, Jiangsu Province, China

Contact Phone: 86-18018236888

E-mail: yongtuo_888@126.com / li@cz-ysd.com